While machines like CNC waterjet cutters work instantly on food items products for cutting, Many others are used for packing or generating cooking equipment. Some common applications are:

In addition, the parts have significant precision and close tolerance finishes, so there is no need to have for secondary procedures. This contributes to faster production instances, expanding the workshop’s efficiency and efficiency.

Because of the skill degree needed to make precision machined parts, quite a few companies will outsource their precision machining Work opportunities regardless of whether they've got CNC machining equipment of their particular.

It could appear surprising to are aware that CNC systems are used inside the Health care sector. Having said that, the applications of CNC machining in Health care and medicine industry are substantial.

Within the construction and agriculture industries, CNC machines are used to make factors for heavy machinery, tools, and structural components. These parts has to be resilient and effective at withstanding severe situations.

Tight tolerances are the main reason to employ CNC precision machining. Tolerance is often called dimensional precision. It refers back to the slight deviation in the dimensions of the machined component from its CAD blueprints.

In order to create superior-top quality machined parts having a modern appearance, it’s important to think about some important things connected with CNC machining.

It employs two electrodes: one particular with the tool and one particular for your workpiece. This machining method brings The 2 electrodes shut to one another but will not create Actual physical touch.

But pretty fantastic attributes and tight tolerances are more durable to obtain manually, and This is when a computer-controlled process subsequent a Kovosvit MAS milling machines digital blueprint definitely arrives into its own.

It operates in an arranged fashion, turning style and design specs into Actual physical parts with Excessive accuracy. Here’s a phase-by-phase overview of its processes:

Outfitted with tools made for extreme accuracy, precision CNC machines can attain tolerances as restricted as micrometres – making them the ideal Alternative when accuracy is on the utmost relevance.

The near tolerances supplied by precision machining are important when factors have to suit alongside one another into a bigger assembly. If the size stray way too significantly from the look, these components might not link effectively, rendering them ineffective.

The metal fabrication industry materials several secondary industries. It relies on CNC procedures like wire EDM cutting, laser cutting, waterjet and plasma cutting to chop massive metal sheets. Other CNC programs can forge these metal sheets into any shape necessary.

CNC machines have remodeled manufacturing throughout a wide array of industries, from automotive and aerospace to clinical and Vitality. As we look to the 2030s, the continued evolution of CNC technology, pushed by advancements in AI, automation, and materials science, will further more enrich the capabilities of those machines.

Alana "Honey Boo Boo" Thompson Then & Now!

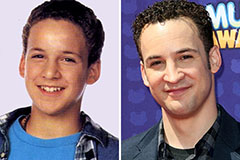

Alana "Honey Boo Boo" Thompson Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!